A new, thin insulator has been designed to boost the energy efficiency of windows by blocking heat.

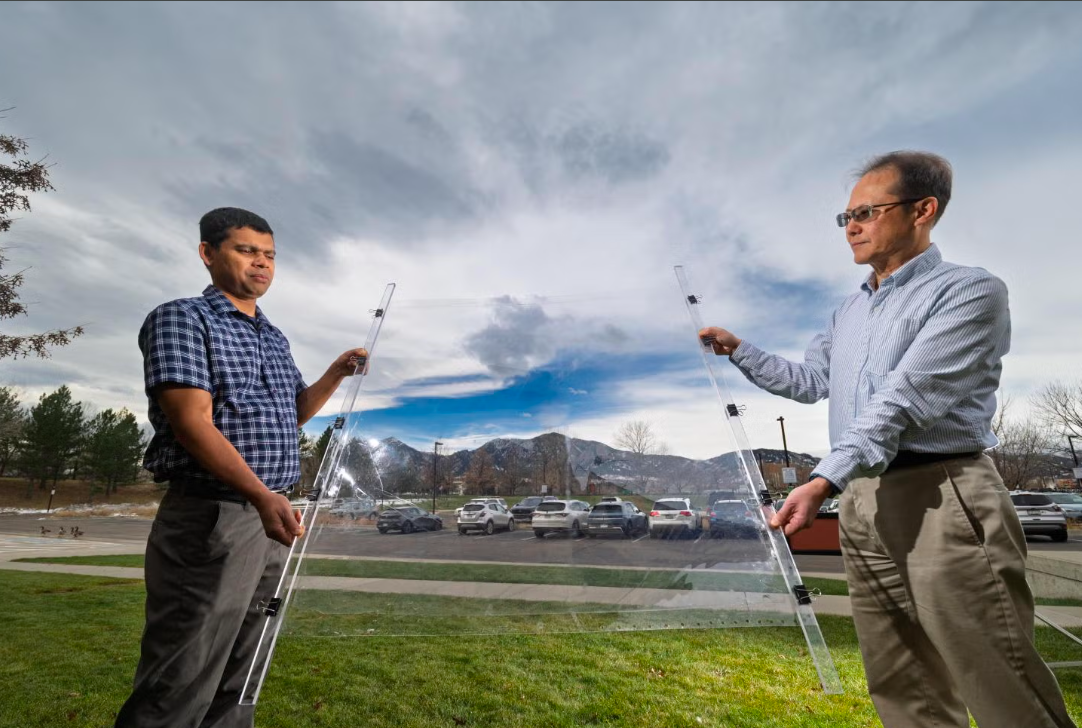

Designed by a team from the University of Colorado Boulder in the US, this invisible window shield material has been dubbed Mesoporous Optically Clear Heat Insulator (MOCHI).

MOCHI has the potential to mitigate the severe global energy waste problem in the building sector. In the US alone, commercial buildings consume over 40% of the power generated.

Interestingly, the long-lasting, almost completely transparent material is available in large slabs or thin sheets for easy application to the inside of any window.

“No matter what the temperatures are outside, we want people to be able to have comfortable temperatures inside without having to waste energy,” said Ivan Smalyukh, a senior author and CU Boulder physics professor, on December 11.

Bubble wrap-like material

The researchers describe MOCHI’s structure as the “high-tech version of Bubble Wrap.”

MOCHI is a silicone gel that is over 90 percent air. The material traps air within a network of incredibly small pores, many times thinner than a human hair.

A five-millimeter-thick sheet leverages those tiny air bubbles to block heat so well that it provides sufficient insulation to hold a flame safely in the hand.

The new invention is an improvement on aerogels, insulating materials often called “frozen smoke” because their randomly distributed air pockets tend to appear cloudy.

NASA uses these older aerogels to keep Mars rovers warm, but they lack the clarity needed for a living room.

Smalyukh’s team carefully designed the fabrication process to achieve transparency.

The creation of MOCHI begins by mixing surfactants (special molecules) into a liquid solution. These surfactants naturally clump together, forming thin threads — a process comparable to oil and vinegar separating.

Silicone molecules in the solution then adhere to the exterior of these surfactant threads, forming the initial structure.

Once the detergent molecules are removed and replaced with air through a series of steps, the remaining structure is silicone, forming a maze of tiny, air-filled channels.

Regular heat transfer works like a game of pool, where energetic molecules bounce off one another, transferring heat.

But in MOCHI’s minuscule air pockets, the gas molecules don’t have enough space to collide with each other. They bounce off the pore walls. This mechanism effectively stops heat flow.

The result is an insulating layer that reflects a mere 0.2 percent of incoming light. Hence, your view remains crisp.

Making energy-efficient windows in the future

MOCHI is currently made in thin sheets in the lab and is not yet available to consumers. However, its potential extends beyond simple window coating.

Engineers envision designing devices that harness MOCHI to trap the sun’s heat, converting sunlight into cheap, sustainable energy for heating water and building interiors, even on cloudy days.

“Even when it’s a somewhat cloudy day, you could still harness a lot of energy and then use it to heat your water and your building interior,” Smalyukh said.

The manufacturing process is currently time-intensive. Nevertheless, the team believes the production method can be made more efficient, aided by the relatively inexpensive materials used.

Whether it’s a home leaking warmth in winter or a skyscraper baking in the summer sun, MOCHI targets the problem of poor thermal exchange through transparent surfaces. It could eventually lead to the future of energy-efficient windows.

The development has been detailed in the journal Science on December 11.